By: Jessi Bienert, Bernhard’s VP of Sustainable Solutions

________________

A 500-Year Storm

The North American winter storm (unofficially referred to as Winter Storm Uri) was a major winter and ice storm that had widespread impacts across the United States, Northern Mexico and parts of Canada from February 13 to 17, 2021. This once-in-500-years storm left 10 million people without power and Middle America was hit hard. Hospitals were among the most critical institutions impacted.

Hospitals in particular have unique interdependencies in their utility types. Power, water, heating, and more are intricately connected in healthcare facilities and any impact to one type of utility could mean disaster. Winter Storm Uri uncovered multiple vulnerabilities in the infrastructure serving hospitals and caused cascading effects. However, many of these issues can be mitigated by effective and efficient energy measures paired with good operations and maintenance practices.

The extreme cold affected gas markets from Texas to Minnesota leading to once-in-a-lifetime gas prices at extreme highs. Multiple electricity wholesale markets also spiked while its infrastructure reached emergency operating levels. In fact, wholesale electricity markets rose anywhere from 100x to 360x normal market prices.

The Brink

In this condition, both electricity and gas distributions were on the brink of shutting down. Hospitals, particularly in the southern states of North America, battled extreme market prices, the inability to receive additional diesel fuel for backup systems and frozen water infrastructure causing loss of water.

This storm affected all utilities because of the interconnection between natural gas, electricity and water. While some hospitals lost utilities for short periods of time, many experienced catastrophic impacts to utility budgets, which have only begun to be realized. In February alone, hospitals saw anywhere from a 65% to 5,000% increase in gas costs. Their inability to mitigate this price shock stemmed from a few key factors:

- Extreme cold weather forced peak natural gas consumption at peak prices.

- There was a lack of price signals from utilities.

- Freeze protection measures and pandemic operations increased peak energy consumption.

Short-Term Impacts

With these factors at play, the situation became dire. Short-term impacts were felt in extreme budget strains, water leaks, negative impacts from energy-saving measures and demand response obligations. One Bernhard client, the University of Arkansas of Medical Sciences (UAMS), purchases natural gas as part of a large pool in Arkansas. While we did explore opportunities to cut back on natural gas during the storm, this set-up enabled the hospital to stay out of the skyrocketing market. Unfortunately, our team at Bernhard saw other hospitals that were not in a pool arrangement incur costs that doubled their annual natural gas budget.

Pragmatically, many facilities in the southern United States were not created to survive such a freeze. That explains why leaks occurred and frozen pipes caused issues for facilities. Many were caught immediately, but underground pipes were not initially observed. Careful monitoring was necessary in the short-term, but is also a consideration for continued management.

During the storm, UAMS ran their facilities on diesel fuel on three occasions in order to reduce the peak load on the power grid serving central Arkansas. However, this actually increased natural gas usage in some ways. The facility’s two heat-pump chillers are unable to run while the facility was on generator power so the hospital still needed to run their natural gas boilers.

Since 2007, UAMS has implemented a strong energy conservation program, reducing its total utility cost by about 65% and cutting its carbon footprint by 30% with Bernhard’s help. But even the most prepared and energy-conscious organizations were greatly impacted by the weather crisis. Many of these occurred due to overcorrections that were never reverted post-crisis. With extensive, consistent monitoring using tools like automatic fault detection, facility operators can automatically identify energy concerns.

Long-Term Impacts

We are still discovering and experiencing the long-term impacts of Winter Storm Uri. Budget concerns will continue to impact future plans for many hospitals. From a legislative perspective (especially in Texas, but also in Oklahoma, Arkansas and other states), there are cascading impacts. Current legislation examines grid reliability and generation assessments, new weatherization requirements, changes to critical customer status, new bond programs and existing utility generation assessments.

On the electricity side, many hospitals take interruptible electricity. This gives them price breaks from their utilities, but means they can be required to cut back from or come off of the grid. On the gas side, most hospitals look for interruptible-type rates, but when that’s not possible, there are provisions and inclusions that actually make you curtailable. In this arrangement, it is imperative that you have a backup utility. All of these factors are important to pay attention to until we see how tariffs and utility rules are changed.

Increased utility rates are one of the many long-term concerns. During this storm, electricity saw high fuel costs as the market costs peaked. While the market stabilized in the short-term, fuel costs are rising again due to storage shortfalls brought about by Winter Storm Uri, those fuel costs will begin cascading down into your electricity costs as a fuel charge. Some states, like Oklahoma, approved new bond programs to allow utility companies to borrow money at a low interest rate so customers can pay over a longer period of time. As a result, the impact will be felt for 13-24 years with a 4-7% cost for electricity, just from those harrowing eleven days.

With so much storage withdrawn during the storm, commodity prices have not come back down to what we saw in 2020. We will continue to see sustained higher pricing in the long-term. Additionally, some utilities have filed to amend their integrative resource plan. This is a long-term plan for generation capacity and they want to amend it to move away from natural gas. This will impact how the cost gets passed down to customers as well and potentially reduce reliance on natural gas for electricity production.

Current Investigations

In the affected areas, most attorney general offices are investigating price gouging and general utility purchasing practices. In Arkansas, for example, the state commission has opened a docket examining how and if utilities are prepared to respond to a storm like this and how the fuel and purchase power is procured and allocated.

There are also federal investigations that look into wrongdoing in the natural gas market. It cost hospitals, customers and utilities billions of dollars, but there are people who made money. The North American Electric Reliability Corporation (NERC), which regulates the electric grid, is working alongside the Federal Energy Regulatory Commission (FERC) to understand the rolling blackouts, both in Texas and two regional transmission markets (covering the entire central United States).

Mitigating Future Risk

For hospitals, patients always come first. There are ways to mitigate future risk and it starts with communication. It’s vital to create a line of communication between commodity suppliers and facility personnel. Your local provider may be focused on keeping you online, but not concerned with the costs. Some of our customers hedged up to 90% of their natural gas and were still heavily impacted by the storm. It’s important to understand how you are purchasing natural gas and understand its impact in a situation like this storm. Review your commodity price risk mitigation plans and make a plan for possible emergency flow orders by keeping your nominations up to date.

Be aware your supplier often takes your monthly nominations and spreads them evenly throughout the month. That’s why it’s important to reduce consumption in non-critical areas and talk to those commodity managers to be sure you’re monitoring closely together. Very practically, you should ensure unoccupied areas are scheduled to minimum heating for freeze protection. We recommend checking this and the maintenance of your steam distribution year-round. One failed steam trap can increase your natural gas consumption by 20%.

Dual-fuel operations are vital, but in order for this to work properly, operators must be comfortable swapping to either fuel. Run each type regularly and check your diesel storage tanks to make sure you have enough fuel for an extended period of time.

Waste heat recovery technology, such as heat-pump chillers, will reduce consumption. Bernhard has clients that realize natural gas savings of more than 50% thanks to this equipment. Plate and frame heat exchangers are excellent tools for efficiency and they are even more important on the heels of this storm. Some of these measures can be time-consuming if you don’t have good control systems, so controls upgrades are a vital part of creating efficiencies.

Other key mitigation measures include:

- Maintaining override logs.

- Managing peak energy consumption.

- Investigating electricity programs that subsidize full back-up power during an NERC level 2 and 3 emergency

- Creating a historical reference guide of utilities failures including cause and detailed procedures to restore.

- Completing vulnerability and gap analysis for utility sources and distribution.

Lessons Learned

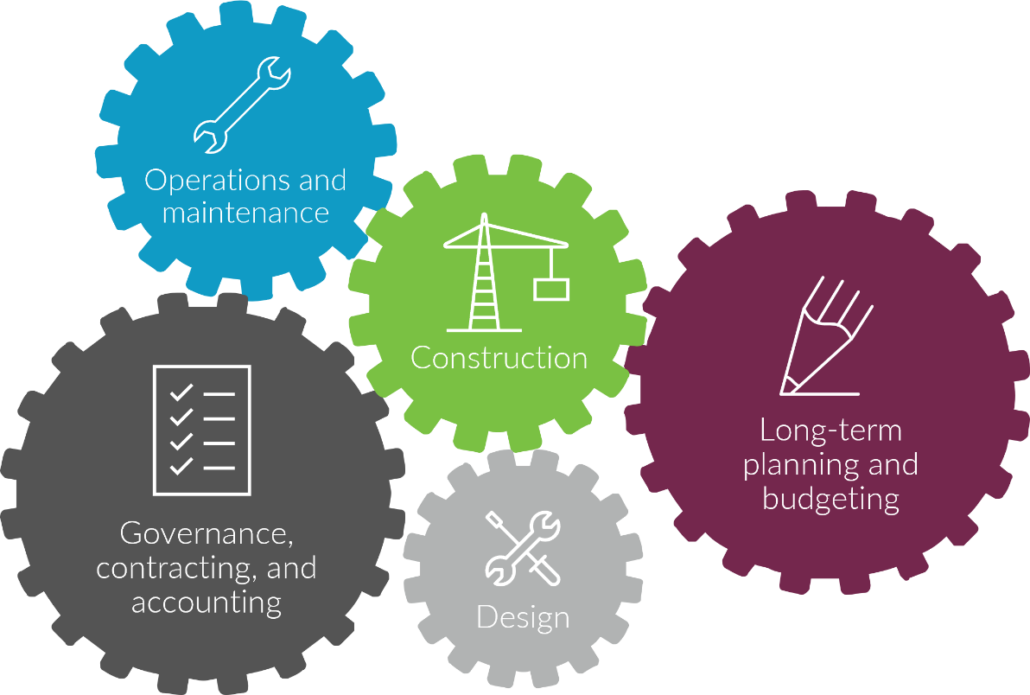

Interdependency between hospital utility types can have catastrophic effects on cost and availability during extreme weather. Now more than ever, we are aware that regulated utilities do not protect consumers from market price spikes; in fact, costs can simply be delayed. Most importantly, there are operational steps that can be taken to mitigate utility price impacts, such as energy efficiency measures. These measures can create resilient facilities against volatile commodity prices, especially when paired with good operations and maintenance practices.

About the Author:

Jessi Bienert has worked at Bernhard since 2009 and most recently served as a Director for the Logic group where she oversaw Bernhard’s measurement and verification, utility analysis, utility management, benchmarking, and O&M training service lines. She is an expert in utility management and specializes in utility rate analysis for large-scale campus energy conservation programs. Jessi is passionate about her work and often advocates on behalf of clients with utility providers to secure the best possible utility rate solutions.

_______________